It was one of those times buying my Tripod on-sale might not have been a good idea. Only after purchasing did I discover this particular Tripod had been discontinued and much to my disappointment extra Quick Release Plates or QR-Plates (Fig 1) we're unavailable.

Needing an extra QR-Plate but never to be beaten into submission by those who would suck me dry of my cash I decided to reverse engineer the part by putting my DIY (do-it-yourself) skills to the task but this was not what was going to happen.

Following is my short story of what was supposed to be a DIY project instead turned into the creation and the reverse engineering of a part by professional and skilled CNC Machinists.

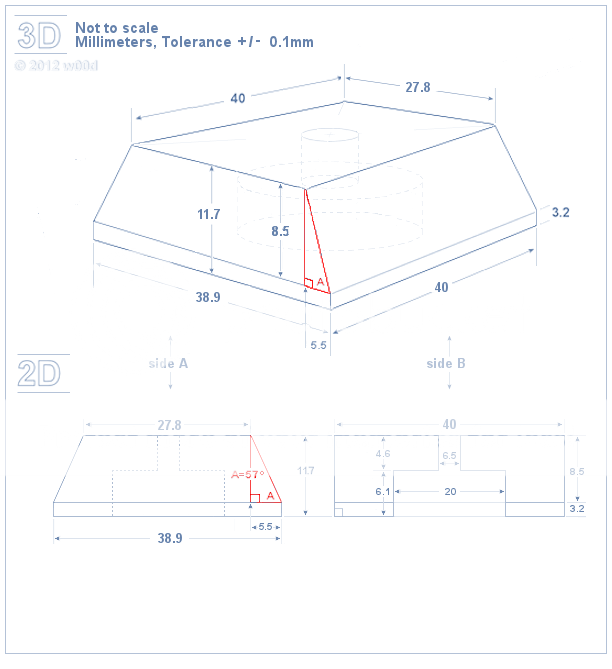

Copying the QR-Plate: My measurements

Copying the QR-Plate: My measurements

|

| Fig 2: QR-Plate measurements |

I wanted to make the new QR-Plate myself and given some materials, time, a Dremel with a few hand tools this was certainly possible. But it was then I realized I have some great friends over at Southern Oregon RC (SORC) who have CNC Machinery therefor they might be tasked to do the work for me, if of course asked very nicely? A skilled CNC operator and his CNC Milling Machine would certainly do a much better, a more professional job than could be done with ordinary hand tools of this hobbyist.

So the next order of business was to ask my good friends if they would be willing to make the part and would they quote me a price if they we're agreeable. They said yes although they didn't give me a price, both friends Tiger and Pelagic Pilot unbeknownst to myself simply got to work making the part.

(Fig 3 and 4) The first CNC Tripod Quick Release produced is made out of aluminum and was fabricated with his CNC Machine by my good friend Tiger (SORC) who is an accomplished engineer. The surprise coming out of this story was him asking me for the angles of two sides of the item I needed cut. At this time he went silent for a few days which left me somewhat puzzled as I thought maybe he had simply forgotten about me. However this was not the case because the next thing I knew much to my delight was a couple of photo's of the finished product and Tiger asking for my shipping address, surprise indeed!

(Fig 5 and 6) The next example is made out of Delrin Acetyl (plastic) and was created by another good friend Pelagic Pilot (SORC) who also runs his own CNC business, BlueFin CNC LLC. From what I could tell given I'm no CNC expert there's quite allot of work between my measurements and the actual cutting of the piece. As I understand Tyson transferred my measurements I had drawn up within a simple photo-editor into his CAD program (Alibre CAD) which creates a .STL file which is then exported into another application (MeshCam). Now armed with the .STL data MeshCam can now creates the necessary 'toolpath' or the path the cutting tool will travel while cutting. Alibre and MeshCam screenshots for those interested.

It's good to have good friends

It's GREAT to have such friends especially when they have the skills and machines to do such wonderful work. Both Tiger and Pelagic Pilot put allot their talent, their time and even their own money into making my project come alive which is certainly appreciated. I don't have enough words to express my gratitude except to say, GREAT job guys, thank you, the world is a better place for having you guys! Yes I'm very excited and can't wait to try them out but now I'm only waiting for the postman ...

It will be interesting to see how the two materials, the aluminum verses the Delrin Acetyl compare. For example the plastic (Delrin Acetyl) will certainly be the lighter of the two materials but the aluminum version might prove more durable?

It's good to have good friends

It's GREAT to have such friends especially when they have the skills and machines to do such wonderful work. Both Tiger and Pelagic Pilot put allot their talent, their time and even their own money into making my project come alive which is certainly appreciated. I don't have enough words to express my gratitude except to say, GREAT job guys, thank you, the world is a better place for having you guys! Yes I'm very excited and can't wait to try them out but now I'm only waiting for the postman ...

It will be interesting to see how the two materials, the aluminum verses the Delrin Acetyl compare. For example the plastic (Delrin Acetyl) will certainly be the lighter of the two materials but the aluminum version might prove more durable?

|

| Fig 3: Machined Aluminum, Side and top © Photo by Tiger |

|

| Fig 4: Machined Aluminum, Bottom © Photo by Tiger |

|

| Fig 5: Beautiful work deserves a nice frame, CNC machined Delrin Acetyl © Photo by Pelagic Pilot .. |

|

| Fig 6: Added Value, rounded corners © Photo by Pelagic Pilot ... |

FYI: So what is a Tripod Quick Release Plate (QR-Plate) you might ask? If your not a photographer or looking to get into photography or you're just curious it's a reasonable question. QR-Plates basically allows for quick mounting and dismounting of a camera onto and from a typical tripod. None of which are standardized as they come in all shapes and sizes all with varying costs to match. Google: Tripod Quick Releases.

|

| Fig 7: Nikon D90 attached |

|

| Fig 9: QR-Plate inserted into the locking mechanism |

|

| Fig 8: QR-Plate locking mechanism |

|

| Fig 10: Sony DSC-H9 mounted. |

|

| Fig 11: QR-Plate Fastener |

|

| Fig 12: Part being copied: QR-Plate and Fastener |

FIN

No comments:

Post a Comment